Pour le besoin d’un procès ou le confort des personnes, il faut pouvoir contrôler l’humidité afin d’éviter la formation de givre et de condensation. Nous vous proposons des solutions adaptées à vos contraintes techniques.

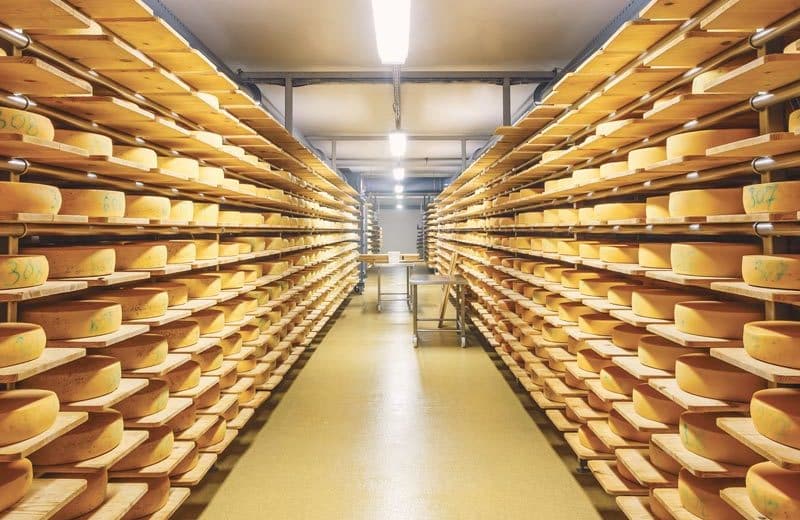

Dans l’industrie agroalimentaire, le traitement de l’air est une préoccupation fondamentale. Le contrôle de l’humidité de l’air, à toutes les étapes de la chaîne de production, permet de garantir la qualité des produits jusqu’à la livraison au client. Certains procédés agroalimentaires sont très sensibles à la qualité de l’air ambiant et une hygiène inadaptée peut entraîner une contamination microbienne (bactéries, moisissures).

L’utilisation d’un déshumidificateur d’air permet d’assécher l’air tout en régulant le niveau d’humidité dans les zones de production. Grâce à des solutions de traitement de l’air appropriées, la qualité des produits n’est plus impactée par les changements de température et la productivité est stable tout au long de l’année.

Principes de conception :

- Élimination de l’humidité à la source

- Maintien des points de rosée faibles empêchant la formation de glace