L’utilisation de peintures à base d’eau au lieu de peintures à base de composants organiques et volatils a entraîné un nouveau problème : la nécessité d’absorber l’excès d’eau de la peinture dans un espace-temps relativement court, afin d’obtenir une peinture de qualité supérieure. Après cette opération, le dernier revêtement de laque peut être appliqué

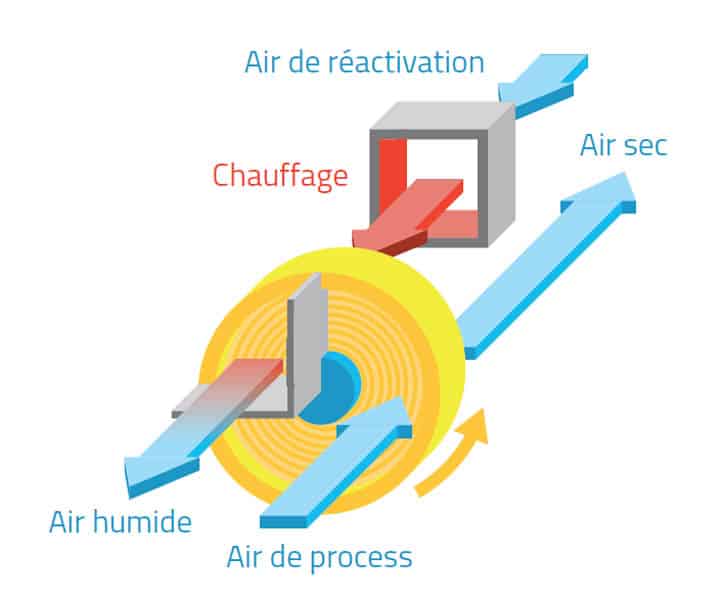

Un four intermédiaire, où se déroule le séchage, est mis en place pour cette installation dans un tunnel de peinture. Les exigences normales pour cette zone sont de 22ºC et 20% d’humidité relative (3,2 g / kg au niveau de la mer). Le débit d’air sec est déterminé en fonction du processus de peinture, de la quantité de peinture appliquée et de l’intervalle de temps. Le déshydrateur sèche uniquement l’air extérieur (entre 15 et 20% du débit total), qui est ensuite mélangé avec l’air de retour. Dans certains cas, les déshydrateurs New’r fournissent également la chaleur nécessaire par le tunnel et, par conséquent, chauffent l’air à 65 ° C tout en le mélangeant avec l’air de retour pour maintenir le tunnel de peinture à 26 ° C. Un tunnel avec des exigences moindres (22ºC et 65% HR) est présenté ci-dessous avec un appareil de traitement d’air subséquente afin de mélanger et de refroidir. Nous pouvons également fabriquer l’ensemble afin d’inclure ces appareils, mais parfois, en raison de leur facilité d’assemblage et de transport, il est préférable d’envoyer seulement le sécheur.